I came across the 1929 edition of a Renold Chain catalogue that lists the chain specifications for a wide variety of motorcycles, motor cars and commercial vehicles. I’ve scanned the page for Sunbeam motorcycles and hope that it is of some use.

Tag Archives: Long stroke

Sunbeam 3-speed gearbox bearings, 1928 and 1929 onwards

Thanks to Chris Fisher for suggesting suitable quality bearings for the 1929 onwards 3-speed gearbox I’m putting together at the moment. The gearbox will be a CT close ratio type and is for a 1928 Model 6 that has been modified in the deep and distant past to house a hybrid OHV motor. The motor employs 1930/1931 crankcases with 1927 single port head breathed on by Chris Odling to take a new Amal 289. So, the whole bike is a “bitsa” but now goes very well with a 7.5:1 forged Model 90 piston from the sunbeamland shop.

I might point the “Model 69″ up a couple of hill climbs once the gearbox rebuild stops it dropping out of 2nd gear and we fit a 19” rear rim – it will then take a pair of the excellent Avon race compound Speedmaster and GP tyres.

1929/1930 Bearings:

- 1 off RHP LJ1-2RSJ

- 1 off RHP MJ7/8-2RSJ

- 2 off RHP KLNJ3/4J

The earlier 1928 wide case box has a smaller mainshaft diameter and consequently an RMS 6 bearing in the case rather than the RMS 7 of the later type. In this case the RHP MJ3/4-2RSJ looks like it could be a good fit.

1928 Bearings:

- 1 off RHP LJ1-2RSJ

- 1 off RHP MJ3/4-2RSJ

- 2 off RHP KLNJ3/4J

With the outer bearings being sealed it might be a good idea to consider implementing a small breather hole in the gearbox filler cap.

1928 Sunbeam Model 6 Longstroke up and running

It was great to get an email from Tony Petherick to say that the new forged piston we supplied was working well in his 1928 Longstroke Model 6. It’s lovely to see one of the iconic Sunbeam models retaining its valanced guards and running with leg shields too. In addition to its lighting kit, the bike also features footboards and an enclosed rear chaincase that hasn’t been lost like so many others.

Tony has fitted more sporting cams to the bike and reports that it runs very well after advancing the inlet cam by two teeth from the marked position. Does anyone have any ideas on cam timing using different cams on these bikes? It was a common “dodge” to fit the 60:30 OHV cams to the sidevalve bikes..

If anyone has a spare petrol cap for the bike please get in touch as the one fitted isn’t quite right and Tony would be keen to give a genuine Sunbeam item a new home.

1927 Sunbeam Motor-Cycle Manual

Thanks to Nick Smith for this copy of the manual for 1927 and earlier Sunbeam motorcycles. Well worth a read if you have one!

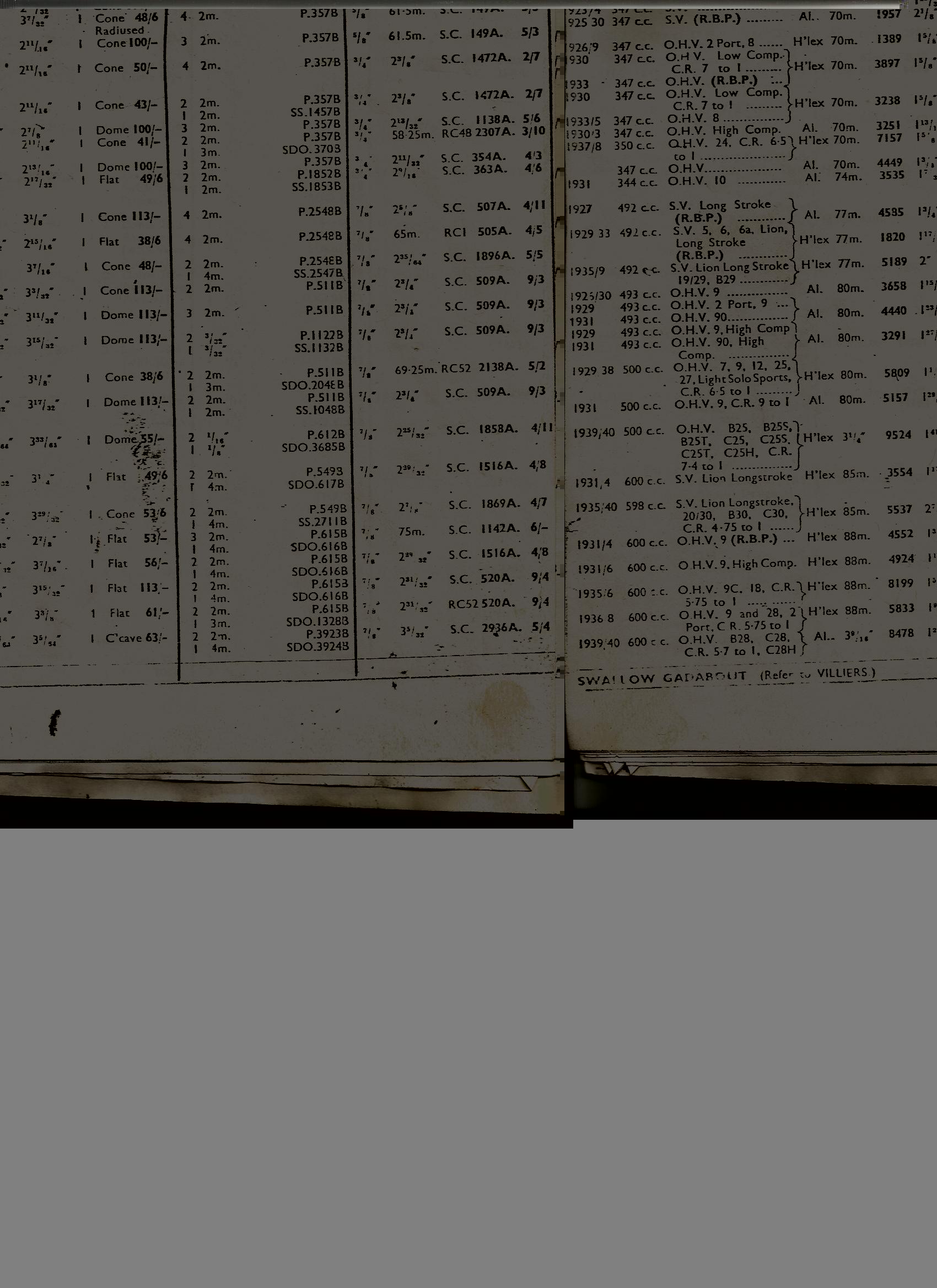

Hepolite pistons for pre-war Marston Sunbeam motorcycles

The ever helpful Vic Youel provided me with this copy of the Sunbeam page from the Hepolite Sunbeam catalogue some time ago. I thought I’d share it as it has proven useful on many occasions.

Marston Sunbeam parts lists now online

Well I’m pleased to say that I’ve just completed an upload of the “final” version of the Sunbeam parts list data base to this website. Nisha and her team of ladies in India who are responsible for a large portion of the data entry have been brilliant working with some very poor copies of the original books. There will be mistakes and omissions in the data so please let me know if any come to your attention and I will make corrections where necessary.

The data base contains nearly 20,000 entries of parts and information from all the original Marston Spare Parts Lists that I could locate over the last 2 years. The parts lists cover most models and variants from 1914 through to 1939 and the web page can be found at this link Marston Sunbeam Spare Parts Lists

I hope it will be well received and of use to owners and also to assist the club and others with planning the production of spares. I appreciate that use of the web page is not necessarily intuitive or stylish but it does seem to at least function and provides the basic set of facilities that I originally intended. Over coming months I’ll make a plan to address this once feedback arrives from users regarding facilities and so on. This work has detracted somewhat from my own bike projects and riding having taken the bulk of any free time over the last 12 months especially and I’m very much looking forward to a break from sitting at this PC in the New Year.

Some hints on Sunbeams

I think we can all benefit from some of the great advice given to my brother by Archie Beggs as an introduction to the joys of vintage Sunbeam ownership:

“To start from cold, flood carb fully, set ignition halfway advanced (some bikes need more). Do not kick it on the stand (these are a bit fragile).

Put bike in bottom gear and wind it back on compression. Then lift the clutch lever fully at the same time pulling back, whereupon you will feel the clutch plates “unstick”.

Select neutral give slight throttle and swing the kickstart smartly but not a vicious kick and if the bike is in good condition it should start.

When started, check the tell-tale is about 1/4″out showing the oil is getting there. This is vital if taps or anti wet-sumping valves have been fitted.

Before putting the bike in gear pause a moment with clutch fully lifted in order to allow the clutch stop (if one is fitted) to slow the clutch to stop and ensure a silent bottom gear engagement without scrunching the gears.

Refrain from being brutal with the gear lever as on the flat tank models the pivot is riveted and soldered to the tank bottom and may be forced loose and cause leaks. Re-soldering the bracket is very difficult as the deposit from the petrol cannot be accessed for cleaning and the solder will not take.

With the cork clutch the plates run oily and I find auto transmission fluid to be suitable, excess slipping causes overheating and severe clutch drag, so get neutral if you are waiting in traffic.

When adjusting clutch, first ensure the lever on the bridge comes right back (cable not tight) so full travel is attained. Then see that the pushrod is free not end loaded and holding the pressure off

When fitting new plates, particularly if Ferodo, be sure that they are wide enough and do not “bottom” on the end of the gearbox mainshaft.

Oil the valve stems before use and put a teaspoonsful of oil to each gallon of petrol to oil the stems

I use the old KLG M80 for normal running and M100 for “blinding” so source modern equivalent but not ones with internal gaps or resistors.

Check tappets when the engine is really hot and make sure there is a couple of thou’ play by feel not the gauge.

Check the three rear wheel bolts after each run and also the stand bolts.

Drain fuel if the bike is left for more than a week and filter before refilling. When drained put a bit of oil in the tank to deter rust,

Do not start the bike in the workshop but in the open and if you start indoors locate fire extinguisher first. Particularly this applies to vintage Rudges.

Use the soft black linings for front brake -this works.

Check gearbox sprocket occasionally

I have always preferred to drain my oil tank when the bike is in only occasional use using a 1/4″ bore plastic pipe and syphoning it out while hot into a large plastic bottle. While this is messy and a nuisance to do, a look at the bottom of the bottle after it has settled for days may convince you it was worth the trouble and as a result all my oil tanks are clean and do not have an 1/8″ of sludge in the bottom. And the engines last longer.

To adjust clutch stop, slack it off fully then lift clutch, then screw it in till you feel the handlebar lever begin to respond to the pressure and try to lift.

Spark plug gap 16 to 20 thou’ not greater

Sunbeam oil regulator orifice sizes

No 1 .046”, 3/64”, No. drill 56

No 2 .060”, 1/16”, No. drill 53

No 3 .077”, 5/64”, No. drill 47

These are the nearest sizes that I can give.”

Sunbeam Model 90 Works Replica Toolbox

The talented Martin Shelley has reproduced a new toolbox assembly to fit saddle tank Model 90 and 95 Sunbeam motorcycles 1929 – 34. This was made as an exact copy of the toolbox and mounts from the only known surviving 1930 works TT Model 90 and features a soldered box with leather front, correct lockable latch, and alloy feet cast in heat treated LM25 and supplied with 1/4” BSF fasteners as per original.

You can see the original box on the 1930 Model 90 that was discovered north of the border a few years ago. Whilst I have yet to fulfil my ambition to examine and scrutinise every inch of that bike I was happy to put my money where my mouth is and buy one of these lovely boxes myself.

Get them while they are hot direct from Martin for a very reasonable £250. Or you could buy the cast feet separately for £50 a pair. If you are interested, why not drop Martin a line on this email marticelli@gmail.com before they are all gone.

Look nice fitted to this delightful Model 90 so they do.

Sunbeam Model 6 Longstroke and Lion pistons now available

Due to a technical problem (I forgot!) the 77mm Model 6 longstroke pistons weren’t available in the shop. I only have a few in standard and +0.040″ oversize so please get in touch if you need a high quality forged piston in your 1925 to 1929 vintage Sunbeam sidevalve.

They can be modified by Chris Odling for use in later engines with the recirculating oil system.

I’m building a 1927 Model 6 motor at the moment that came with a 1928 Model 6 that I purchased recently and one of these should work very well in the new engine.

Sunbeam Model 6 Longstroke pistons now in stock

Following on from the successful production of pistons for OHV 500cc Sunbeam models Chris Odling and I thought it would be useful to produce some high-quality forged pistons suitable for the Model 6 side valve long-stroke. The Model 6 was produced from 1922 until 1939 becoming known as the Lion after takeover by ICI. With its 77mm x 105.5mm bore and stroke this was the last side valve powered motorcycle to win a Senior TT.

There were of course changes along the way and the piston produced is nominally compatible with models produced from 1925 until 1929. Before 1925 a 5/8″ gudgeon pin was used rather than the later 7/8″ type and the change to a scavenge pump from total loss oiling in 1930 means a different piston ring configuration is required. It is possible that these pistons could be adapted to suit.

I have limited availability of pistons in 77.0mm +0.000″ and +0.040″ sizes. An all-up weight of 434g has been achieved for the 77.0mm which is within 2g of the target weight that we set out to achieve.

Once we have given the new items a good look-over I’ll be contacting those who have reserved pistons already and adding them to the Sunbeamland shop.