A great day out in the sun was had by all at this year’s Les Newman Memorial Run. The day was organised by ace restorer John Phizacklea and hosted by Rob and Joe Selbourne at Prebendal Farm, Bishopstone. Next year the event may well be opened to other marques but this year at least it was well supported with 13 of Marston’s finest taking a spin around the 40 mile track route.

The event is a tribute to local hero Les Newman who raced his Sunbeams throughout the ’30s and famously used the lanes around the area as “practice” for his races on the Isle Of Man. My own ’30 Model 90 was raced by Newman at the 1934 Manx Grand Prix where he was given a special award following his 69.28mph lap “in recognition of a fine ride on a 4 year old”. After missing last year’s run it was great to finally bring the bike back home and to enjoy the lanes it must have known so well. I’m not sure that Les found time to stop for a pint on the way round his course but if he ever did, I’m sure that he wouldn’t have found this gentleman guarding the entrance to the hostelry where we stopped for a quick one.

With John taking his own 95 for a spin there were indeed some fine bikes enjoying the superb roads and scenery including a JAP twin and Parallel 9 amongst the Model 9s, 90s and side-valves.

As I habitually use a van to transport the bikes I was shamed by the distances that had been ridden to the event by some of the participants. Jez Cator, who had ridden up from Portsmouth and camped over-night at the farm, was rightly presented the furthest distance travelled award by Vic Youel. The day was rounded off back at the world’s tidiest farm with a fine spread of sandwiches and cake. More photos from the day can be viewed here.

However, I was particularly excited to see the ex-Smedley 95 that John has recently acquired and that young Chris let off the leash for a canter around the lanes.

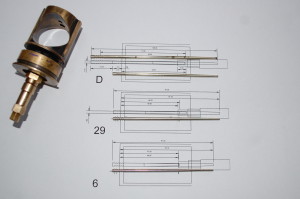

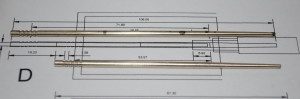

The amazing story and history of the Smedley bikes surely deserves recording and telling in much more detail than I can even begin to attempt here. However, being built for race, sprints and hill-climbing by the Rolls-Royce engineer the bikes represent the absolute pinnacle of engineering excellence. They weigh next-to-nothing but with over 50hp at the rear wheel I am sure you can imagine the result.

Having had Chris blast pass me earlier in a blur of speed, noise and Castrol R, I was keen to take the bike for a short spin. I have to say that it really was a staggering, eye-opening experience. The low gearing obviously helps but the bike just pulls, revs and accelerates like a mad thing and it is easy to believe the 3 sec 0-60mph times are quite possible. Despite the performance on hand, it was surprisingly easy to ride at sensible speeds too with just the occasional pop and bang to let you know it was getting impatient for the taps to be opened. This amazing bike could take on and shock even modern sports bike riders, at least with the right rider on board it could….